From Udder to Fridge

Do you know how dairy cows are milked?

Have you ever wondered how milk gets from a dairy cow to your glass? It’s a rather simple process but it does involve a lot of hands!

After the cow must give birth, the process of producing milk begins. Once the cow is producing, she will head to the milking parlor.

There are four common types of milking parlor designs in the commercial dairy industry: parallel, herringbone, tandem, and rotary. Which parlor design a dairy uses may be based on the size of the farm, how many cows are being milked each day, available labor, finances related to building, or the original design of the farm (A majority of dairies are older, generational farms.)

Let’s take a look at each design style (Design graphics courtesy of Dairy Discovery Zone.)

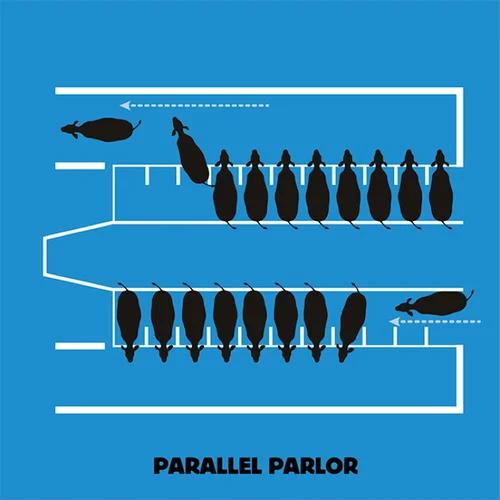

Parallel

In this style, cows stand next to each other and face straight away from where the milker will be (at the tail side). Many times this will have a bar system or head catch that is in place to prevent the cows from leaving the parlor until all milking is complete

Milking typically takes about 10 minutes

In this design, groups of cows enter and exit at the same time, not as individuals, which can a pitfall of this design. Milkers can either be at a lower level from the udders, or at the same height, just depending on the dairy.

See how the shoulder bars prevent the cows from moving forward out of the parlor? This gate will be lifted when milking is complete and all cows can exit as a group.

Herringbone

A herringbone parlor functions the same as a parallel parlor, except the cows stand at a 45-degree angle from the milker. This vantage point allows different access points to the udder and can be advantageous for certain equipment use. Again, the milker may be on a lower level than the cow or at the same level. Just as in the previous design, groups of cows enter and exit at the time in this fashion.

See how the cows present at more of an angle to the milker? This presents a different vantage point than the parallel style.

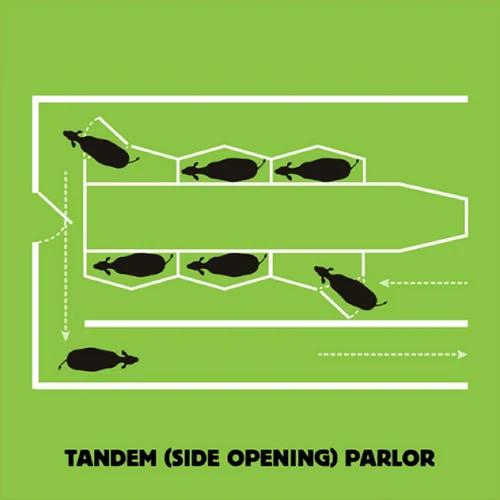

Tandem

In a tandem parlor style, cows can move as individuals rather than a group. Each stall as an entrance and an exit allowing cows to come and go at their own pace and not have to wait for the entire group to finish milking.

The disadvantage to this style is that much fewer cows can fit in the parlor at one time, slowing overall herd milking times down, increasing the time and labor dedicated to each milking. This style is typically used in smaller dairies.

Here you can see the milker has a side profile of the cows. Some tandem style parlors have cows enter and exit as a group where others have animals move as individuals.

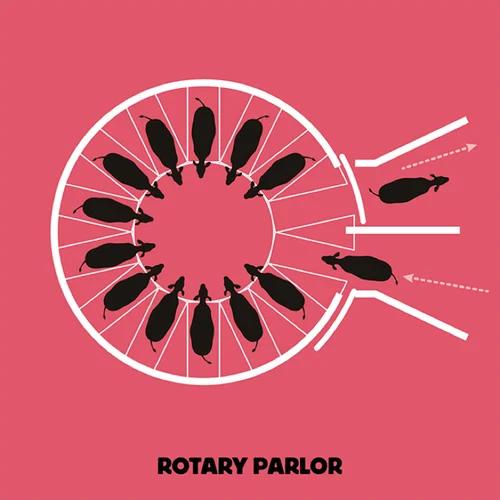

Rotary – A rotary milker is like a merry-go-round for dairy cows. True to its name, this parlor actually spins (or rotates) around the room constantly and cows enter/exit at one location. Milking is completed by the time a cow makes the full circle (or two) and milkers stand on the outer edges to perform the milking.

The platform continues to rotate at a slow pace, similar to a revolving door, the cattle enter and exit when the opportunity presents.

All-day cleanliness

Dairy cows will enter these parlors 2-3 times a day and stay there for somewhere between 7 and 15 minutes for milking. The milk is fed through the tubing to a large bulk tank where it begins to be chilled to the proper temperature.

Dairies are extremely aware of the cleanliness required to provide safe, wholesome milk. Each teat is cleaned and tested before milking equipment is placed on the udder and disinfected once equipment is removed.

Milk is routinely tested for any cause for concern, in fact, many milking systems are so intelligent and data centered now that it records how much milk each teat is producing for every single cow and can test the quality of that milk before it reaches the bulk tank—problematic milk is diverted away from the bulk tank and the dairy is alerted to the issue which that cow so they can investigate the cause.

The bulk tanks, where all of the milk is combined, is tested for antibiotics, somatic cells, and other contaminants before it ever leaves the farm. Once everything is clear, the bulk tank is emptied into a semi and onto the processing plant where it will be pasteurized and processed (have fat removed, etc.).

A typical dairy will empty their bulk tank every day or few days, but larger dairies will empty their bulk tank multiple times a day into multiple semis each time.

Most fluid milk goes from the cow to your grocery in less than 2 days!

About the author

When not tending to her own 17-acre farm, Michelle Miller aka The Farm Babe is a writer, public speaker, and social media influencer on food and modern agriculture. Learn more about her at thefarmbabe.com.

Tags:The Farm Babe

Acreage Life is part of the Catalyst Communications Network publication family.